SOLUTIONS FOR THE LAMINATED GLASS INDUSTRY

In design and architecture there are no limits for creativity. So there is, likewise, an infinite need for new ideas and innovation. The construction industry is similarly driven by a desire to push boundaries and defy the elements.

For more than 13 years in the distribution of EVA films, we cover the individual needs of our customers with our know-how and the optimal film.

With evguard® we supply the right product and enable our customers to implement their innovative ideas.

Thanks to our multi-layer technology, our product combines the properties of various polymers in one film.

The EVA film evguard® is the result of many years of research and development. Manufactured in Germany using European raw materials, we deliver consistent quality every time.

EvGuard® is increasingly used worldwide as an EVA-based interlayer in the laminated glass industry. Due to its excellent “cure torque” strength, its wide processing temperature range, its long shelf life, its excellent optical properties and its adaptability to processing / handling in small vacuum ovens, but also on a large scale in autoclave processing, EvGuard® is equally suitable for the glazing business as well as industrial production on a large scale.

EvGuard® is manufactured exclusively in Germany, with raw materials from certified, also exclusively European suppliers. The films do not contain any plasticizers and have excellent compatibility with a large number of other materials. For example, it is also possible to laminate wood veneers, stone panels, LCD and LED foils, fabrics, fabrics or metal grids as well as printed foils. Due to the three-dimensional cross-linking of the molecular chains during processing, EvGuard® is not a thermoplastic, but a thermoset. After lamination, the foils are absolutely temperature-stable and cannot be melted again.

EvGuard® films are therefore suitable for both indoor and dedicated outdoor use. The proven good moisture resistance and sound insulation round off the properties of this very special film.

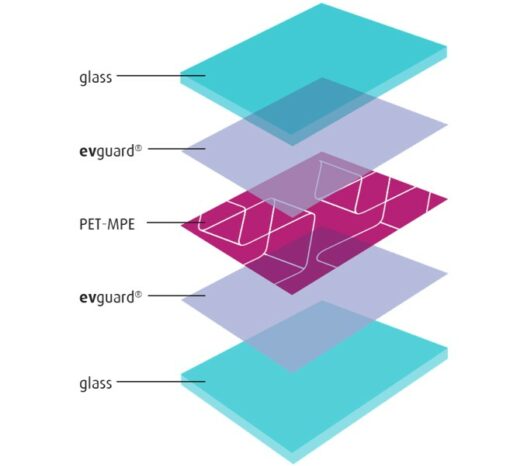

In addition to the EvGuard® laminating film, our EvGuard® MPE can also be embedded into the glasses for design purposes or for glasses with the highest mechanical stress. EvGuard® MPE is a „multilayer“ polyester which enables the highest security properties. It can even be printed on.

EvGuard® is certified according to all common standards worldwide and our possible customizing is another additional benefit:

EvGuard® can be ordered in individual dimensions from a relatively small number of rolls, both project-related and customer-specific requirements.

Please do not hesitate to contact us. We would be happy to send you the relevant documentation.

WHAT IS evguard®?

evguard® is an elastic interlayer film for laminated glass. Based on an ethylene vinyl acetate copolymer that when heated, creates a highly cross-linked, three dimensional composite, bonding the glass together to manufacture certified, safety and security glass.

With its outstanding properties, evguard® is at the forefront in the premium sector of laminating films for the glass industry. Having successfully carried out impact testing using the pendulum and drop ball methods we have also tested for weathering performance and sound reduction values.

With all current certifications for Europe, North America and Germany (DiBT) passed, we offer our partners a value added product.

Folienwerk Wolfen GmbH also offers a PET-MPE film („100 % modified copolyester“). In combination with the evguard®, evguard® MPE establishes an additional advantage in terms of stability, durability, shear modulus effect and printability. evguard® and evguard® MPE can be processed by using the existing suggested cycle times for normal lamination.

The laminated glass withstands high thermal loads. evguard® MPE can be incorporated into the composite as a transparent, colored or printed interlayer, thus providing the desired design. To summarise: using evguard® and evguard® MPE together, a high impact resistant glass can be produced and if needed this can be printed on to make a decorative safety/security product.

The cross-linking and quality make the difference

Glass creates a sense of openness and transparency, and so is progressively becoming more and more important, for example, in architecture. The transparent building material is increasingly integrated in the façade engineering, both as individual surface and as entire glass front. These applications put great demands on the laminated safety glass that traditional materials usually cannot meet.

During the lamination process, evguard® undergoes the crosslinking process and remains in an irreversible state between the glass panes of the laminated safety glass. This cross linked state of evguard® prevents the film from losing its stiffness in the case of wind and heat. Compared to polyvinyl butyral (PVB), a thermoplastic laminating material that softens at higher temperatures, this is one of the most significant benefits of evguard®. Façades, especially frameless glass fronts, thus remain stable over a broad range of environmental influences. As a result, evguard® provides greater stability and improved optics of the laminated glass. Another essential feature plays an important role: compared to PVB, evguard® is less hygroscopic.

Diverse processing possibilities

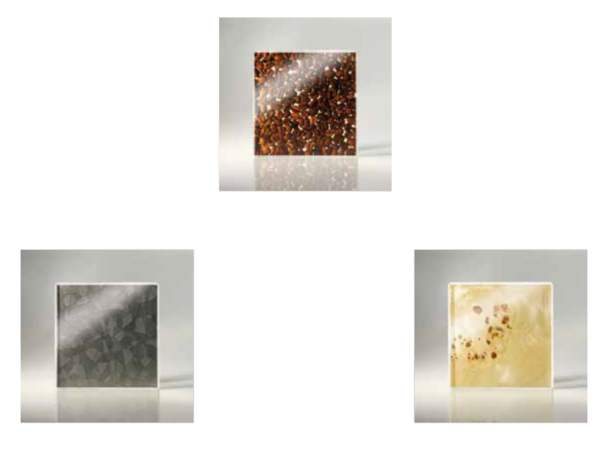

Above all, evguard® stands out due to excellent processing possibilities even at lower temperatures. Temperature-sensitive inserts can be laminated into the composite – whether colored films, photos, marble, sandstone, metal mesh, coffee beans, blades of grass, bamboo or wherever your imagination takes you.

CONTACT

BB Laminating Solutions GmbH

Theodor-Storm-Str. 9

57413 Finnentrop

Phone: +49 151 2275 20 14

Email: christian.buecker@bb-ls.de

GLADLY I WILL CALL YOU

Christian Bücker

Managing Director